How We Make Chocolate

Our work begins after the hard work by the cacao producer is done. Before we see the cacao beans, they have been harvested, fermented, dried, sorted and shipped directly by our farmers or our direct trade brokers.

Clean

We first clean the beans, removing extraneous material like twigs and stone, any damaged cacao beans, and any "flats and smalls", cocoa beans that are distinctly smaller or flatter than average. Flats and smalls are set aside for a separate treatment and processing.

Roast

Next, we roast the beans. The beans are roasted in our 100+ year old, repurposed Royal No. Five coffee roaster. Built in New York, this cast iron and steel beauty lets us gently roast our precious beans and coax out all the desired flavour. Roasting has several goals including: removal or small amounts of residual water, puffing out the shell (which helps in removing the shell a little later in the process); and as temperatures rise, chemical changes continue - the flavour transforms from fermented acidity to the delightfully complex chocolate flavours that we all know and love. As an added bonus, the heat of the roasting process sterilizes the bean.

Winnow

This goal of this stage is to remove the hard outer hull of the bean. This can be done by hand, but it is very time consuming, and wreaks havoc on your fingernails! This clever contraption is a combination of bean cracker and winnower which, using suction and gravity, separates the hull from the bean. The result of this stage is cacao nibs, which are roasted and cracked cacao beans.

Melange

This is the stage where cacao is turned into chocolate. Through a combination of heat, pressure, and friction, the cacao nibs (pre-heated) are liquified by grinding them between the granite wheels and granite base of one of our refiner/melangers, the machine at left. This tool pulverizes the liquified cacao for 2-4 days depending on the bean type. Sugar and any spices or other flavouring are added during this stage.

Temper and Bar

Once the chocolate comes off the melanger, we may let it age.

When we are ready to turn the block chocolate into bars, we temper the chocolate and pour into our molds. By heating the chocolate to a specific temperature, lowering it, and carefully raising it again, the fatty acid crystals within the chocolate align into a stable form. A good temper holds the chocolate stable over time, limits melting in the hand, and produces the wonderful snap of a great chocolate.

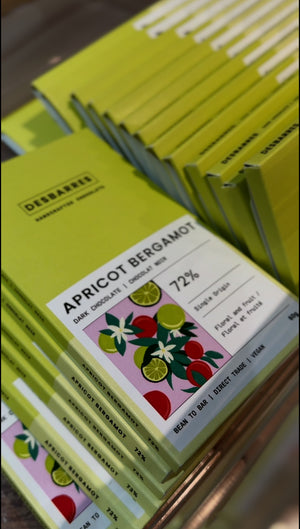

Package

Our bars are then packaged. Our chocolate is first protected in a glassine pouch. Glassine is not waxed or chemically-finished during manufacturing, and glassine bags are food safe, fully recyclable, compostable and biodegradable. The final outer packaging is FSC grade paper. Your entire chocolate bar packaging can be put in your paper recycling.